Alteryx Designer Desktop Discussions

Find answers, ask questions, and share expertise about Alteryx Designer Desktop and Intelligence Suite.- Community

- :

- Community

- :

- Participate

- :

- Discussions

- :

- Designer Desktop

- :

- Using Spatial Objects to create a custom map.

Using Spatial Objects to create a custom map.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

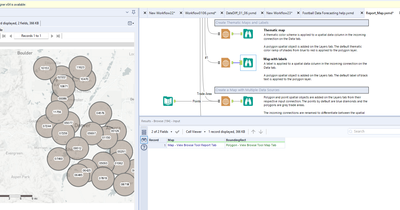

I'm exploring if I can use the spatial objects tools to create a layout of my machine shop and then use transaction data to show how much material is at what work center. As you can see in the picture I've laid out a template of machines (squares) and then joined it with the data at the machine (items with diamond). Is there a way to add details to the spatial objects, like descriptions and details like qty, age, job#'s? I can't seem to find a way to add words to the "Map". Thanks for any ideas/help.

- Labels:

-

Spatial Analysis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi @Tybo!

I second @binu_acs suggestion of the Report Map tool. There actually are a lot of formatting and labeling options because you can build layers.

Just wanted to comment that this is such a cool and creative use case! I do something similar with Tableau for workstations, but I never considered doing it with Alteryx. I am inspired! Thank you!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@ddiesel I'm glad I've inspired you!

My manager is in the process of getting Tableau so if I can't get this to work effectively that will be our backup plan.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is a really interesting use case. Are you implementing KANBAN for supply tracking?

Clear Channel Outdoor

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@Hollingsworth Hi John, We have abandoned the "LEAN KANBAN" for a system driven Min/Max method as the "human" aspect of running a Kanban proved to be very difficult to accomplish. This use case will not be for a KANBAN system but rather a visual way to inform our machine shop planners what work may be stagnated at each work center, track progress from operation to operation and to help level load the machines. I still have not been able to accomplish this in an effective way as the tools do not quite work the way I'd like (Labeling and adding data to the labels is a bit tricky if even possible). I've since given up because the time I'm spending on this out weighs the benefit because I've already created a very useful report that does this but without the visual layout.

-

Academy

6 -

ADAPT

2 -

Adobe

204 -

Advent of Code

3 -

Alias Manager

78 -

Alteryx Copilot

26 -

Alteryx Designer

7 -

Alteryx Editions

95 -

Alteryx Practice

20 -

Amazon S3

149 -

AMP Engine

252 -

Announcement

1 -

API

1,209 -

App Builder

116 -

Apps

1,360 -

Assets | Wealth Management

1 -

Basic Creator

15 -

Batch Macro

1,559 -

Behavior Analysis

246 -

Best Practices

2,695 -

Bug

719 -

Bugs & Issues

1 -

Calgary

67 -

CASS

53 -

Chained App

268 -

Common Use Cases

3,825 -

Community

26 -

Computer Vision

86 -

Connectors

1,426 -

Conversation Starter

3 -

COVID-19

1 -

Custom Formula Function

1 -

Custom Tools

1,939 -

Data

1 -

Data Challenge

10 -

Data Investigation

3,488 -

Data Science

3 -

Database Connection

2,221 -

Datasets

5,223 -

Date Time

3,229 -

Demographic Analysis

186 -

Designer Cloud

742 -

Developer

4,374 -

Developer Tools

3,532 -

Documentation

528 -

Download

1,037 -

Dynamic Processing

2,941 -

Email

928 -

Engine

145 -

Enterprise (Edition)

1 -

Error Message

2,261 -

Events

198 -

Expression

1,868 -

Financial Services

1 -

Full Creator

2 -

Fun

2 -

Fuzzy Match

713 -

Gallery

666 -

GenAI Tools

3 -

General

2 -

Google Analytics

155 -

Help

4,711 -

In Database

966 -

Input

4,296 -

Installation

361 -

Interface Tools

1,902 -

Iterative Macro

1,095 -

Join

1,959 -

Licensing

252 -

Location Optimizer

60 -

Machine Learning

260 -

Macros

2,865 -

Marketo

12 -

Marketplace

23 -

MongoDB

82 -

Off-Topic

5 -

Optimization

751 -

Output

5,258 -

Parse

2,328 -

Power BI

228 -

Predictive Analysis

937 -

Preparation

5,171 -

Prescriptive Analytics

206 -

Professional (Edition)

4 -

Publish

257 -

Python

855 -

Qlik

39 -

Question

1 -

Questions

2 -

R Tool

476 -

Regex

2,339 -

Reporting

2,434 -

Resource

1 -

Run Command

575 -

Salesforce

277 -

Scheduler

411 -

Search Feedback

3 -

Server

631 -

Settings

936 -

Setup & Configuration

3 -

Sharepoint

628 -

Spatial Analysis

599 -

Starter (Edition)

1 -

Tableau

512 -

Tax & Audit

1 -

Text Mining

468 -

Thursday Thought

4 -

Time Series

432 -

Tips and Tricks

4,187 -

Topic of Interest

1,126 -

Transformation

3,731 -

Twitter

23 -

Udacity

84 -

Updates

1 -

Viewer

3 -

Workflow

9,982

- « Previous

- Next »