Alteryx Designer Desktop Discussions

Find answers, ask questions, and share expertise about Alteryx Designer Desktop and Intelligence Suite.- Community

- :

- Community

- :

- Participate

- :

- Discussions

- :

- Designer Desktop

- :

- Re: Truck planning optimization

Truck planning optimization

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

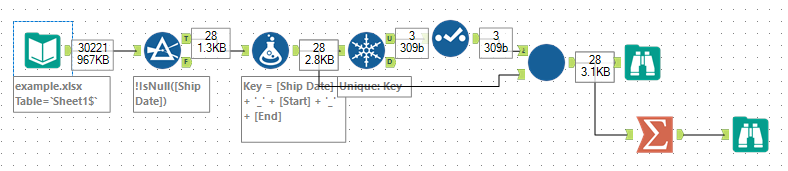

I am new to optimization with Alteryx. I have a basic truck planning problem which is grouped by Date, Start and End locations. The objective is to determine which combination of weights to go together to minimize the number of trucks. We cannot combine weights from other groups. The max capacity of a truck is 44,000

Also attaching an example file. Any help is appreciated.

Thanks!

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi @ayadav8,

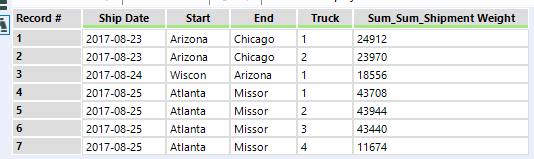

Thanks for your question! An iterative macro will allow you to do this planning. (You may need to wrap in a batch macro in order to take each group individually).

Here is a great knowledgebase article describing Iterative Macros.

Here is an on-demand training video for Iterative macros.

Hope this helps!

Amelia

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@AmeliaG thanks for the suggestion but when I tried connecting it to my problem, it is confusing me. I tried looking at other community posts but I am still unclear.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's a really interesting (and computationally complicated) problem.

As @AmeliaG said I think the best approach is a combination of batch and iterative macros. We run an allocation for each day, start and end (using a batch macro to pick each set).

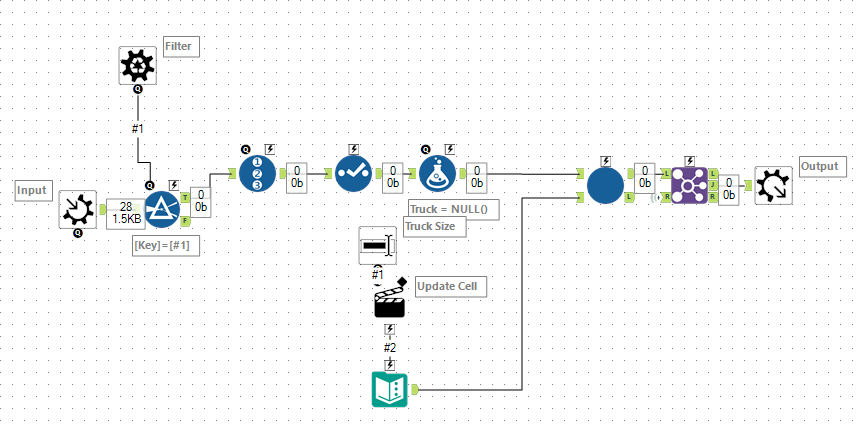

The allocation engine I have put together works off an idea from @Claje:

- Working from largest item down to smallest

- Assign to an existing truck if there is space otherwise add a new truck and assign there

This is built as an iterative macro.

The first block picks the next item to allocate

The block at the bottom decides which truck to assign the item to or adds to new one

Finally, we record the allocation and then see if anything else left to iterate over

I think this approach will give a reasonable answer. I can imagine there could be edge cases where it does not produce the optimal answer however though.

Hope it helps you get started

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is really great. Thanks so much @jdunkerley79

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

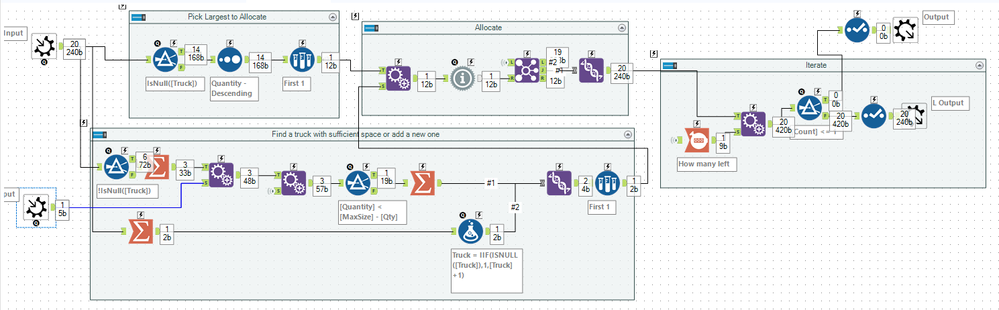

Hi, how do we change the max truck size?

-

Academy

6 -

ADAPT

2 -

Adobe

204 -

Advent of Code

3 -

Alias Manager

78 -

Alteryx Copilot

25 -

Alteryx Designer

7 -

Alteryx Editions

94 -

Alteryx Practice

20 -

Amazon S3

149 -

AMP Engine

252 -

Announcement

1 -

API

1,208 -

App Builder

116 -

Apps

1,360 -

Assets | Wealth Management

1 -

Basic Creator

14 -

Batch Macro

1,558 -

Behavior Analysis

246 -

Best Practices

2,693 -

Bug

719 -

Bugs & Issues

1 -

Calgary

67 -

CASS

53 -

Chained App

268 -

Common Use Cases

3,823 -

Community

26 -

Computer Vision

85 -

Connectors

1,426 -

Conversation Starter

3 -

COVID-19

1 -

Custom Formula Function

1 -

Custom Tools

1,936 -

Data

1 -

Data Challenge

10 -

Data Investigation

3,486 -

Data Science

3 -

Database Connection

2,220 -

Datasets

5,221 -

Date Time

3,227 -

Demographic Analysis

186 -

Designer Cloud

740 -

Developer

4,368 -

Developer Tools

3,528 -

Documentation

526 -

Download

1,037 -

Dynamic Processing

2,937 -

Email

927 -

Engine

145 -

Enterprise (Edition)

1 -

Error Message

2,256 -

Events

198 -

Expression

1,868 -

Financial Services

1 -

Full Creator

2 -

Fun

2 -

Fuzzy Match

711 -

Gallery

666 -

GenAI Tools

3 -

General

2 -

Google Analytics

155 -

Help

4,705 -

In Database

966 -

Input

4,291 -

Installation

360 -

Interface Tools

1,900 -

Iterative Macro

1,094 -

Join

1,957 -

Licensing

252 -

Location Optimizer

60 -

Machine Learning

259 -

Macros

2,862 -

Marketo

12 -

Marketplace

23 -

MongoDB

82 -

Off-Topic

5 -

Optimization

750 -

Output

5,252 -

Parse

2,327 -

Power BI

228 -

Predictive Analysis

936 -

Preparation

5,167 -

Prescriptive Analytics

205 -

Professional (Edition)

4 -

Publish

257 -

Python

855 -

Qlik

39 -

Question

1 -

Questions

2 -

R Tool

476 -

Regex

2,339 -

Reporting

2,431 -

Resource

1 -

Run Command

575 -

Salesforce

277 -

Scheduler

411 -

Search Feedback

3 -

Server

629 -

Settings

933 -

Setup & Configuration

3 -

Sharepoint

626 -

Spatial Analysis

599 -

Starter (Edition)

1 -

Tableau

512 -

Tax & Audit

1 -

Text Mining

468 -

Thursday Thought

4 -

Time Series

431 -

Tips and Tricks

4,187 -

Topic of Interest

1,126 -

Transformation

3,726 -

Twitter

23 -

Udacity

84 -

Updates

1 -

Viewer

3 -

Workflow

9,974

- « Previous

- Next »